Make your paper cutting tasks seamless and accurate with Colordowell's Hydraulic Programmed Paper Cutter Model 6710L. This hydraulic paper cutter, designed with top-tier technology, provides a solution to all your paper cutting needs. With a maximum cutting width and depth of 670mm and a minimum cutting depth of 30mm, this machine offers you ultimate versatility. Capable of efficiently handling a maximum cutting thickness of 80mm, this robust product is built to last.

The key highlight of this hydraulic cutting machine is the paper press mode, a combination of hydraulic and mechanical power. This feature ensures that your paper is held firmly to maintain its original positioning accuracy during the cutting process. The hydraulic cutting method also enables automatic paper push for precise positioning and final adjustments.

Another striking feature of this paper cutter is its program control that allows for 100 sets of 20 dollars, displayed on a user-friendly 10 touch screen interface. Furnished with grating protection, this paper cutting machine doesn't compromise on safety.

When it comes to colordowell products, we take pride in maintaining high-quality standards. Despite being power-packed with features, the weight of the machine is 520 kgs while the gross weight is 560 kgs. The compact size of the machine ensures it doesn't consume excessive space in your work area.

Colordowell's Hydraulic Paper Cutter stands out in the market for its dual hydraulic paper cutting and pressing mechanism. The machine's clutches for these two mechanisms are both hydraulically driven, distinguishing it as a fully hydraulic or dual hydraulic paper cutter.

Colordowell, a recognized manufacturer and supplier, is committed to excellence and innovation. Trust our Hydraulic Programmed Paper Cutter Model 6710L for an unparalleled paper cutting experience. We aim to offer high-quality, reliable, and efficient paper cutters to make your operations smoother. With Colordowell, you choose precision, quality and durability. Step into the future of paper cutting with Colordowell's Hydraulic Paper Cutter 6710L.

Immerse yourself in the technological marvel that is the Hydraulic Paper Cutter 6710L, brought to you by Colordowell, known for their industry-leading innovation and quality. This product defies market norms by delivering immense cutting capability without compromising on paper cutting machine price. With its maximum cutting width and depth sitting at a robust 670mm, this machine represents a revolution in the paper cutting industry. The device also boasts an impressive minimum cutting depth of 30mm and a maximum cutting thickness of 80mm.

A standout feature of this state-of-the-art machine is the depth of the knife edge table that extends to 420mm. This allows for an unparalleled cutting experience that promises both precision and consistency. Furthermore, the Hydraulic Paper Cutter 6710L upholds an exceptional standard of paper cutting accuracy of ±0, making it one of the most reliable machines in the realm of paper cutting.

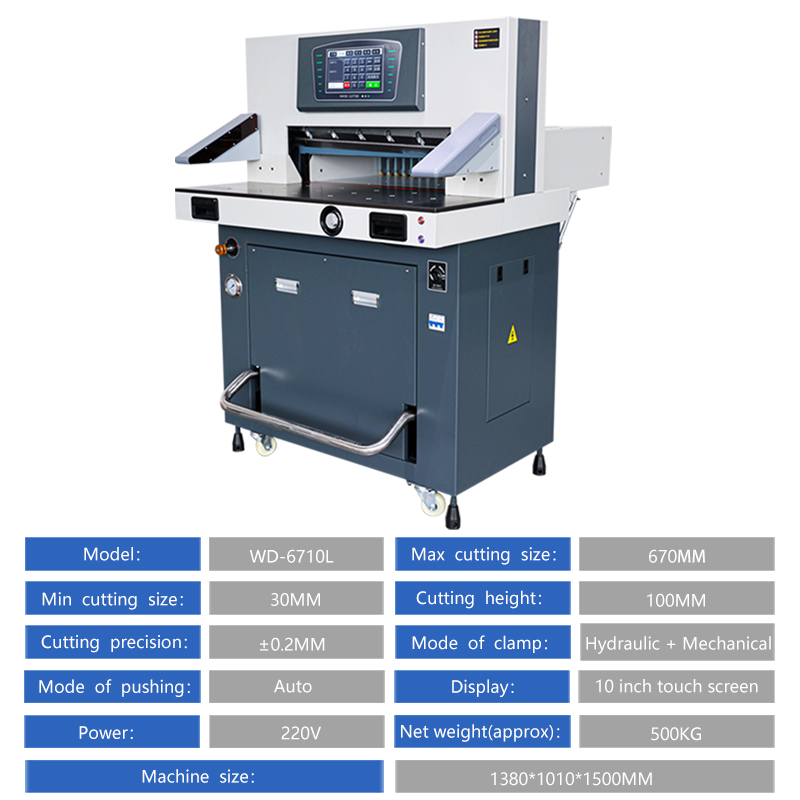

Specifications:

The Maximum Cutting Width : 670mm

Maximum Cutting Depth: 670mm

Minimum Cutting Depth : 30mm

The Maximum Cutting Thickness : 80mm

The Depth Of The Knife Edge Table : 420mm

Paper Cutting Accuracy: ±0.3mm

Paper Press Mode:Hydraulic + Mechanical

Paper Cutting Method: Hydraulic | Push Paper :Automatically

Program Control :100 Sets *20 Dollars

Display: 10 "Touch Screen

Power Ac220v (110v)±10% (50hz/ 60hz)/ 3.1 Kw

Net Weight Of The Machine : 520kgs

The Gross Weight Of The Machine : 560kgs

Machine Size: 1780*1150*1370mm

Package Size: 1850*1280*1590mm

Grating Protection : Yes |

Structure:

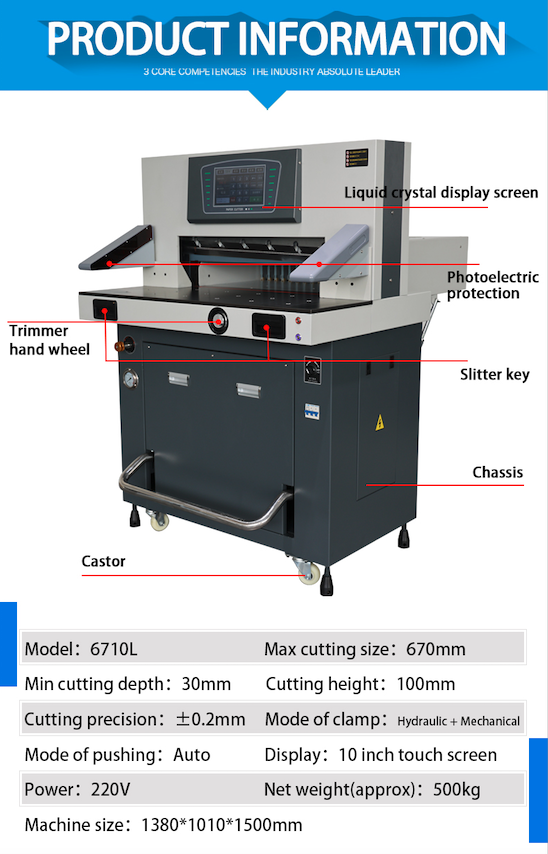

The paper cutter is mainly composed of a host machine (also called a gantry), a workbench, a paper pushing mechanism, a paper pressing mechanism, a cutting mechanism, etc. The paper pushing mechanism is used to push the paper for positioning and make final adjustments. The paper pressing mechanism presses the positioned paper tightly to ensure that the original positioning accuracy is not destroyed during the cutting process. The cutting mechanism is used to cut the paper, and the side baffles are used for The side block gauge and the workbench play a supporting role. From the driving mode of the paper pressing mechanism, it is divided into mechanical paper pressing and hydraulic paper pressing.

The clutches of the paper pressing mechanism and the cutting mechanism are both hydraulically driven, which is also called a fully hydraulic or dual hydraulic paper cutter. Fully hydraulic or dual hydraulic paper cutters have greater cutting force and have obvious advantages when cutting high-density cutting materials. The clutch is not easy to slip and there is no need to frequently adjust the clutch clearance.

Detailed Picture:

In addition to the remarkable specifications, the device upholds Colordowell's commitment to quality and innovation. This is evident in its highly robust design that ensures a long lifespan and minimal maintenance requirements. It is no wonder that Colordowell's Hydraulic Paper Cutter 6710L is garnering so much attention for its performance capabilities and its competitive paper cutting machine price.

In conclusion, the Hydraulic Paper Cutter 6710L is an embodiment of Colordowell's dedication to providing consumers with high-quality, efficient, and cost-effective solutions. This innovative device is surely the epitome of value for money, marrying top-tier functionality with an incredibly affordable paper cutting machine price. Whether for commercial or personal use, Colordowell's Hydraulic Paper Cutter 6710L is undoubtedly the perfect tool to take your paper-cutting needs to the next level.