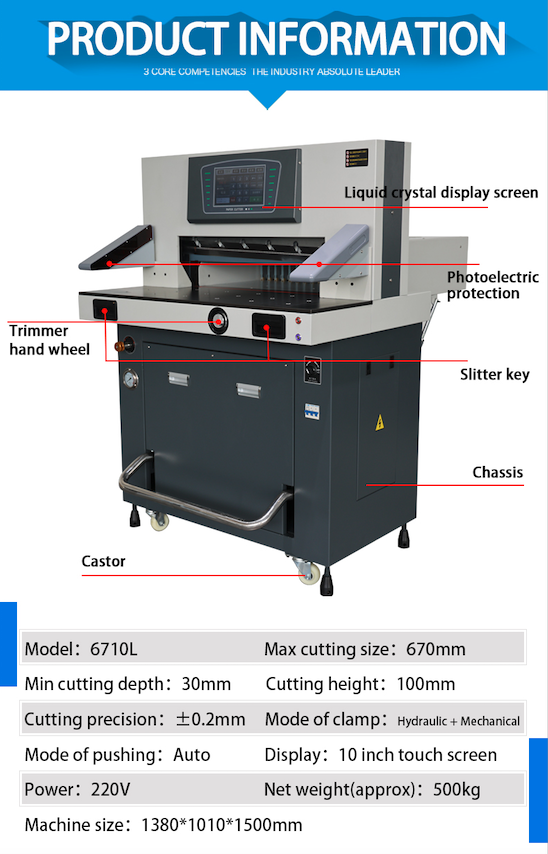

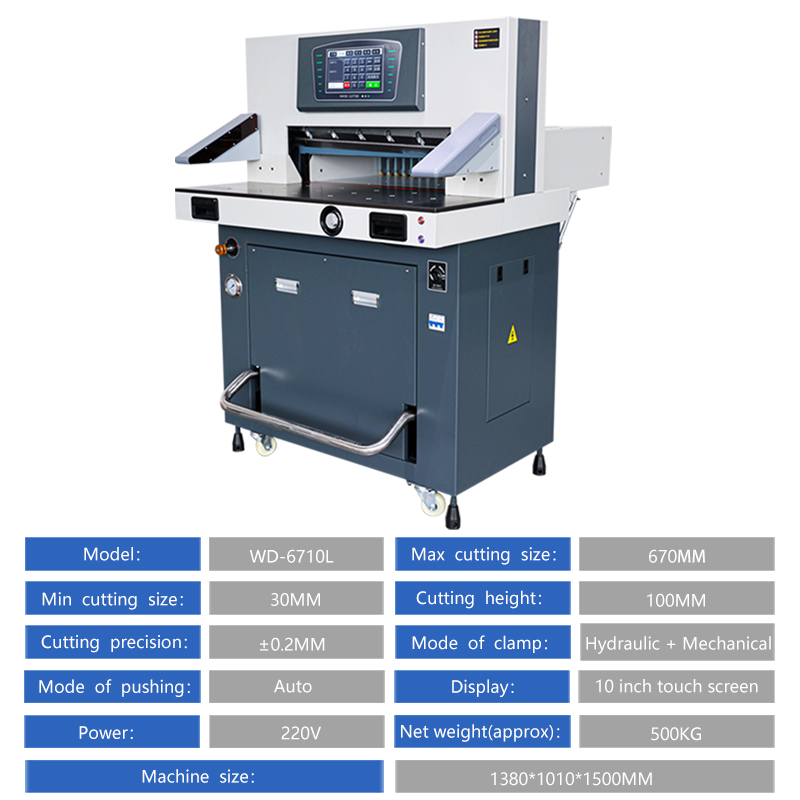

Make your paper cutting tasks seamless and accurate with Colordowell's Hydraulic Programmed Paper Cutter Model 6710L. This hydraulic paper cutter, designed with top-tier technology, provides a solution to all your paper cutting needs. With a maximum cutting width and depth of 670mm and a minimum cutting depth of 30mm, this machine offers you ultimate versatility. Capable of efficiently handling a maximum cutting thickness of 80mm, this robust product is built to last.

The key highlight of this hydraulic cutting machine is the paper press mode, a combination of hydraulic and mechanical power. This feature ensures that your paper is held firmly to maintain its original positioning accuracy during the cutting process. The hydraulic cutting method also enables automatic paper push for precise positioning and final adjustments.

Another striking feature of this paper cutter is its program control that allows for 100 sets of 20 dollars, displayed on a user-friendly 10 touch screen interface. Furnished with grating protection, this paper cutting machine doesn't compromise on safety.

When it comes to colordowell products, we take pride in maintaining high-quality standards. Despite being power-packed with features, the weight of the machine is 520 kgs while the gross weight is 560 kgs. The compact size of the machine ensures it doesn't consume excessive space in your work area.

Colordowell's Hydraulic Paper Cutter stands out in the market for its dual hydraulic paper cutting and pressing mechanism. The machine's clutches for these two mechanisms are both hydraulically driven, distinguishing it as a fully hydraulic or dual hydraulic paper cutter.

Colordowell, a recognized manufacturer and supplier, is committed to excellence and innovation. Trust our Hydraulic Programmed Paper Cutter Model 6710L for an unparalleled paper cutting experience. We aim to offer high-quality, reliable, and efficient paper cutters to make your operations smoother. With Colordowell, you choose precision, quality and durability. Step into the future of paper cutting with Colordowell's Hydraulic Paper Cutter 6710L.

Experience cutting-edge efficiency with Colordowell's large paper trimmer – the Hydraulic Paper Cutter 6710L. Designed to offer maximum precision, this premium cutting tool boasts a maximum cutting width and depth of 670mm, setting new industry standards. Whether your project involves thick or thin paper, our large paper trimmer can handle a wide range of thicknesses, with a maximum of 80mm and a minimum of just 30mm.

With an impressively deep knife edge table of 420mm, you can rest assured that your work will have that professional finish every time. But what sets our large paper trimmer apart is its unfaltering accuracy; the Hydraulic Paper Cutter 6710L guarantees a paper cutting accuracy of ±0. This means that every trim and slice will be exactly where you want it to be, with no room for error.

Specifications:

The Maximum Cutting Width : 670mm

Maximum Cutting Depth: 670mm

Minimum Cutting Depth : 30mm

The Maximum Cutting Thickness : 80mm

The Depth Of The Knife Edge Table : 420mm

Paper Cutting Accuracy: ±0.3mm

Paper Press Mode:Hydraulic + Mechanical

Paper Cutting Method: Hydraulic | Push Paper :Automatically

Program Control :100 Sets *20 Dollars

Display: 10 "Touch Screen

Power Ac220v (110v)±10% (50hz/ 60hz)/ 3.1 Kw

Net Weight Of The Machine : 520kgs

The Gross Weight Of The Machine : 560kgs

Machine Size: 1780*1150*1370mm

Package Size: 1850*1280*1590mm

Grating Protection : Yes |

Structure:

The paper cutter is mainly composed of a host machine (also called a gantry), a workbench, a paper pushing mechanism, a paper pressing mechanism, a cutting mechanism, etc. The paper pushing mechanism is used to push the paper for positioning and make final adjustments. The paper pressing mechanism presses the positioned paper tightly to ensure that the original positioning accuracy is not destroyed during the cutting process. The cutting mechanism is used to cut the paper, and the side baffles are used for The side block gauge and the workbench play a supporting role. From the driving mode of the paper pressing mechanism, it is divided into mechanical paper pressing and hydraulic paper pressing.

The clutches of the paper pressing mechanism and the cutting mechanism are both hydraulically driven, which is also called a fully hydraulic or dual hydraulic paper cutter. Fully hydraulic or dual hydraulic paper cutters have greater cutting force and have obvious advantages when cutting high-density cutting materials. The clutch is not easy to slip and there is no need to frequently adjust the clutch clearance.

Detailed Picture:

Perfect for businesses large and small, our cutting-edge paper trimmer is a favorite amongst professionals looking for efficiency, precision, and reliability. No other paper trimmer combines such a wide variety of features into one compact, user-friendly design. So, whether you are in the printing industry, work in an office, or need a reliable paper cutter for your school or university, Colordowell's Hydraulic Paper Cutter 6710L is your perfect choice.

Discover a new world of precision with our large paper trimmer - designed and engineered for those who refuse to compromise on quality. Choose Colordowell, where innovation meets functionality.