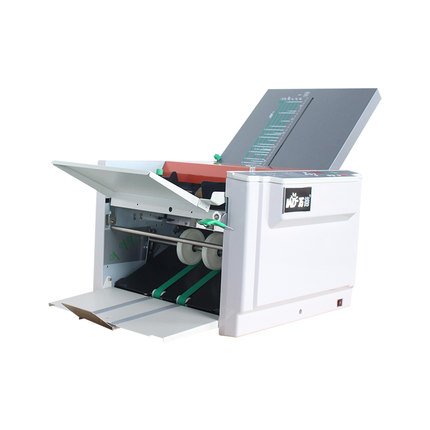

Colordowell's WD-306 Automatic Paper Folding Machine: High Efficiency & Precision

Structure:

Paper feeding part

It is divided into two types: flat paper feeding device and continuous paper feeding device. The paper feeding device is mainly responsible for separating and conveying paper, and can accurately convey the printed pages to the folding part.

Folding mechanism

The fence folding mechanism is a mechanism that uses a fence to cooperate with a relatively rotating folding roller and a steering baffle to complete the folding. It is mainly composed of a folding roller and a folding fence.

Delivery part

The paper delivery part can adopt the form of a movable paper delivery trolley. The paper collecting trolley can adjust the height and angle according to the origami style. It also has an independent stepless speed adjustment function that can be adjusted according to the folding speed.

Working Principle:

An origami machine is a machine that folds flat paper into complex patterns. Its working principle involves multiple steps and parts, which are described in detail below:

1.Paper input: Origami machines usually use paper roll input, and the paper feed amount is adjusted as needed to ensure the coordination of paper feed speed and folding time.2.Paper tension control: Since the thickness and material of paper vary, changes in the paper feed speed will affect the paper tension. The origami machine automatically adjusts the paper feed speed and tension through sensors and controllers to ensure the quality and accuracy of origami.3.Cutting and punching: Origami machines are usually equipped with automatic cutting and punching devices for cutting and punching holes during the folding process to ensure the softness and easy folding of the origami.4.Folding action: The origami machine realizes precise origami actions according to the folding angle and direction set by the program through transmission mechanisms, sliders, gears and other parts, and is equipped with electric eyes and sensors at the folding points to detect the accuracy of the folding points. position and folding angle.

5.Data control: Origami machines are usually equipped with computer controllers that can adjust the size, style and quantity of folds as needed, and can store and call program codes for multiple folding patterns to meet the needs of different users.

Specifications:

| Feeding mode | automatic |

| Paper size | Max. 300mm×435mm |

| Min. 100 mm * 130 mm | |

| paper thickness | 60g/ m2-157 /m2 |

| Suitable paper | copy paper, writing paper, double tape paper |

| Feeding capacity | 400 sheets (70g/m) |

| Count | 0000-9999 |

| Folding speed | 40-100 pages/min / 2400-6000 pages/hour (70g /m A4) |

| Power supply | AC 220V,50Hz 135W |

| Machine size | 790mm(W)×490mm(D)×525mm(H) |

| Service size | 920mm(W)×490mm(D)×525mm(H) |

| N.W. /G.W. | 33 kg / 38 kg |

Video