Colordowell WD-V350 Roll Laminator - Your Superior Choice for Film Laminating and Thermal Processing

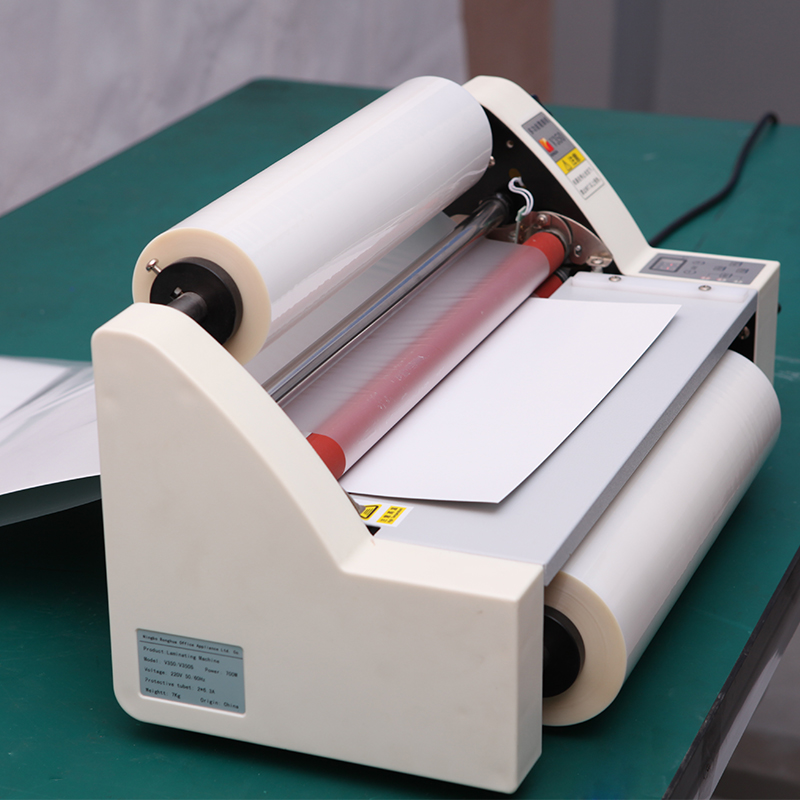

Introducing the Colordowell WD-V350 Roll Laminator, a top-tier solution for all your film laminating needs. As a leading supplier and manufacturer, Colordowell has elevated this product with a series of features that streamline laminating while boosting the quality and longevity of your laminated materials.

The WD-V350 Roll Laminator boasts three modes of operation: dual-sided laminating, single-sided laminating, and cold laminating. Its unmatched versatility makes it an irreplaceable asset in any setting that requires frequent laminating, such as offices, schools, or print services.

Designed for durability and precision, this thermal laminating machine features electronic temperature control with a digital display, ensuring accurate and reliable results every time. The machine's laminating thickness ranges from 0.1-5mm for maximum flexibility in handling different materials.

Powered by a high silica roller, the WD-V350 excels in high-temperature resistance and rapid heat-up. It can laminate up to a maximum width of 350mm, making it ideal for various paper sizes, including A3 and A4. The laminator includes four robust rollers that guarantee even heat distribution and smooth laminating process.

Sleek and durable, the WD-V350 is crafted with a high-temperature resistant ABS cover that withstands impacts, ensuring it retains its aesthetic appeal even with extensive use. Designed for easy transportation, it ships in a double corrugated carton with protective foam inside, minimizing the risk of damage on transit.

When you choose Colordowell's WD-V350 Roll Laminator, not only do you get an exceptional laminating machine, but you also enjoy the peace of mind that comes with using a product from a trusted manufacturer. Choose Colordowell, your reliable partner in premium laminating solutions.

Previous:WD-R202 Automatic folding machineNext:WD-M7A3 Automatic Glue Binder

1. Electronic temperature control,Digital display,Accurate and reliable;

2.Multifunction laminating:double side laminating/single side laminating/cold laminating;

3.Laminating thickness from 0.1-5mm;

4.High silica riller with high temperature resistanceand fast heated laminating size up to 350mm

5.Processing in moulds,products and durable ABS Covers,beautiful,surface,high temperature,resistance,impact resistance;

6.Double corrugated carton with foam inside avoiding damage during transportaion.

| Max Width | 350mm |

| laminating thickness | 80-350g |

| Speed | 1.1m/min |

| Paper feeding method | Manual feeding paper |

| Film core | 1inch of diameter (2.54cm) |

| heating method | Rubber |

| Pressure roller diameter | 25mm |

| Temperature | 70-110℃ |

| Number of rollers | 4 |

| Display method | Digital tube display |

| Control method | Button control |

| Pressurization method | Spring control |

| Paper feeding method | Manual feeding paper |

| Working model | cold laminate, single laminate, double laminate |

| Voltage | 220V(110V Optional ) |

| Power | ≤700W |

| WEIGHT | 7/8Kg |

| Dimension(L*W*H) | 530* 210* 220mm |

Previous:WD-R202 Automatic folding machineNext:WD-M7A3 Automatic Glue Binder